This programme is available to all Manufacturing companies from all European or Horizon Europe associated countries

Here's how you can make your machines last longer with AI completely free of charge

APPLICATIONS ARE CLOSED!

Applications are closed, but stay connected! Be the first to know about future openings.

What is AIDEAS?

AIDEAS is developing AI technologies to optimize every stage of an industrial machine's life, from its initial design all the way through to its eventual recycling.

Become an Early Adopter and benefit from:

50%

Increase in machine performance

80%

Decrease in machine calibration time

15%

Reduction in design development time

With this, you'll receive:

FREE TESTING

For a select number of testers

PERSONALISED OFFER

From leading European Technology providers

Discover all the 5 suites and choose the one that fits better your manufacturing process characteristics.

Test drive our AI solutions

Industrial Equipment Design Suite

Simplify and streamline your design process, ensuring that even if you are facing a skills gap or resource shortage, you can still produce reliable, customer-tailored solutions with ease.

Transform the way you design industrial equipment with cutting-edge, AI-powered tools and generate innovative, cost-effective and resilient product designs.

This AI-powered suite enables your business to effortlessly make simulations easy through the use API and UI and gather data from those simulations, leverage it for optimisation in mechanisms and dynamic machines.

This suite enables you to overcome the challenges of manual design methods, set a new standard in machine construction and align your products with market demands.

Main benefits:

- Optimises the product design considering wear evolution

- Shortens the design development time

- Analyses product behavior in early-stage designs

- Increases machine operation accuracy and efficiency

- Reduces product time-to-market

Solutions Included:

AIDEAS Machine Design Optimiser (AIMDO): Define the key design parameters in multi-physical systems, enhancing machine performance as required for each scenario, through AI.

AIDEAS Machine Synthetic Data Generator (AIMDG): Synthesize large datasets

through simulations for the analysis of the machine design.

AIDEAS CAx Addon (AICAx): Take of advantage of a set of APIs and UIs supporting the integration of AI-assisted optimisation modules into CAx systems.

Use cases:

Meet BBM, an extrusion blow molding (EBM) machine manufacturer that is paying more and more attention to ecological and sustainable aspects. Using the AIDEAS Industrial Equipment Design Suite, BBM will be able to reduce machine end-of-life costs by 15% and shorten the design cycle times by 20%.

Moreover, this suite will enable them to also reduce machine downtime, energy consumption and extend the machine’s lifecycle. This will grant the company the opportunity to enhance the agility, sustainability and resilience of EBMs through their entire life cycle.

Leading Developers:

To download this information click HERE

Industrial Equipment Manufacturing Suite

Get a more predictable and efficient production line, with better product delivery schedules and faster market reach. Streamline procurement, fabrication, and delivery plans, using smart algorithms that adapt to your plant’s unique challenges. Make informed decisions in real-time and optimise every stage from procurement to delivery with AI-driven solutions.

Make informed decisions in real-time and optimise every stage from procurement to delivery with AI-driven solutions.

From procurement to delivery, these solutions enable an optimised version of your procurement, fabrication, and delivery plans, using intelligent algorithms.

These solutions help machinery manufacturers stay ahead of its competitors in terms of efficiency and speed, while also setting a new standard for planning in the machine construction industry.

Main Benefits

- Improves storage planning, control, utilisation and flexibility

- Shortens overall production time

- Improves resource purchasing

- Optimises resource utilisation

- Ensures on-time, cost-effective and environmentally friendly product delivery

Solutions Included

AIDEAS Procurement Optimiser (AIPO): Optimise your inventory, material

purchase and customer deliveries dates using AI.

AIDEAS Fabrication Optimiser (AIFO): Predict production, set-up times and

respond in real time to machine breakdowns, last minute customer orders and raw materials delays, all through AI.

AIDEAS Delivery Optimiser (AIDO): Control your storage space, storage conditions and product transportation, all through AI.

Use Case

Here’s Multiscan, an artificial vision equipment manufacturer struggling to cope with customer requirements, reduction of bottlenecks and optimisation of industrial processes. Using the AIDEAS Industrial Equipment Manufacturing Suite, Multiscan has achieved remarkable results. With AI-powered toolkits, including production and scheduling algorithms, Multiscan will be able to reduce machine manufacturing downtime by 10% and decrease the production loss ratio by 15%.

Moreover, the industrial equipment manufacturing suite will enable them to enhance resource allocation, improve procurement plans, maximise shipping container volume utilisation, decrease maintenance costs, and increase production efficiency. This will allow the company to improve the entire production process and achieve cost-effective and eco-friendly product delivery.

Leading Developers

To download this information click HERE

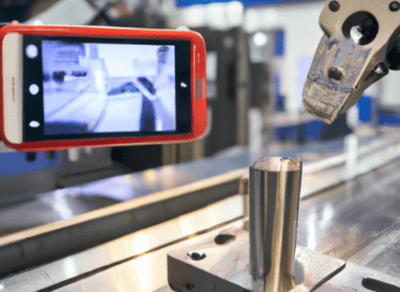

Industrial Equipment Use Suite

Go beyond the minimal data input. Take advantage of fast machinery condition evaluation and early anomaly detection. Streamline your processes, while also guaranteeing product quality and defect-free production.

Get AI technologies that bring added value to the user. This suite ensures optimal installation and adaptive control of industrial equipment.

From initial calibration to automated visual inspections, these solutions streamline your production processes from the user perspective.

For equipment manufacturers, these solutions also support a guarantee of product quality and defect-free production, ensuring heightened operational efficiency and reliability.

Main Benefits

- Shortens installation times and costs

- Speeds up the defect localization process

- Automates the Machine Calibration Process

- Reduces scraps, waste and rejected goods

Solutions Included

AIDEAS Machine Calibrator (AIMC): Get AI to speed up your calibration process for your equipment, for the first time or when a re-calibration is needed.

AIDEAS Condition Evaluator (AICE): Determine the real-time condition of your machine as a whole or its components, when it is in working conditions in the plant.

AIDEAS Anomaly Detector (AIAD): Detect anomalies from component-level to the entire machine when it is in working conditions in the plant.

AIDEAS Adaptive Controller (AIAC): Embrace our advanced toolkit to train models with measurement data and seamlessly train your machine controllers to accommodate any machine condition and requirement.

AIDEAS Quality Assurance (AIQA): Elevate your quality monitoring and enjoy a comprehensive set of features designed to enhance your product quality.

Use Case

Here’s D2Tech, a CNC equipment manufacturer for the stone sector, struggling to handle the complexity of the natural stone, of which the quality cannot be controlled, and with the machine‘s optimisation reduce

installation time.

Using the AIDEAS Industrial Equipment Use Suite, D2Tech will be able to increase machine performance by 50% and decrease the time and skills required to calibrate the machine by 80%.

Moreover, this suite will enable them to reduce energy consumption, maintenance costs and machine downtime. This will grant the company the possibility to increase their turnover rate, increase turnover exports

and relocate operations to new markets.

Leading Developers

To download this information click HERE

Industrial Equipment Repair-Reuse-Recycle Suite

Extend your machine’s lifecycle and upgrade your industrial equipment. Specifically for maintenance and production managers, this suite optimises machine parameters and resource usage.

Control your equipment, extend its operational life and reduce new purchases. Our AI-based solution supports data-driven decision-making and foster a circular production model, focusing on repairing, reusing, and recycling industrial equipment.

Control your equipment, extend its operational life and reduce new purchases. Our AI-based solution supports data-driven decision-making and foster a circular production model, focusing on repairing, reusing, and recycling industrial equipment.

This approach not only maximizes productivity and the residual value of materials but also emphasizes recycling

over downcycling, aligning with sustainable and efficient manufacturing practices.

These features create a powerful tools for equipment manufacturers looking to enhance equipment longevity, optimize resource usage, and support environmentally responsible production methods.

Main Benefits

- Extends the machine’s lifecycle

- Reduces machine component waste

- Shortens machine recycle time and cost

- Reduces machinery maintenance times

- Ensures responsible end-of-life for machines

Solutions Included

AIDEAS Prescriptive Maintenance (AIPM): Predict your machine’s remaining useful life and identify maintenance requirements with the target of extending the overall machine lifecycle.

AIDEAS Smart Retrofitter (AISR): The retrofitting tool to give old machines a

second life, enabling the monitoring and analysis of key operating parameters

AIDEAS LCC/LCA/S-LCA (AILC): Identify the best machine end-of-life by devising a multi-objective optimisation strategy.

AIDEAS Disassembler (AIDIS): Streamline your recycling processes and enable object recognition and identification with cameras and sensors, allowing for enhanced disassembly and material circulation.

Use Case

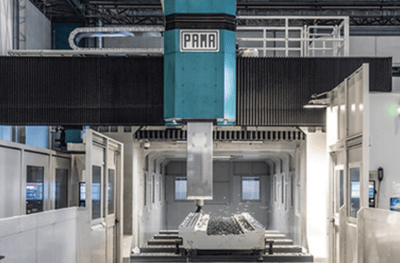

In PAMA, a boring-milling machines and machining centres manufacturer, is interested in becoming a circular-enabled manufacturer.

PAMA, a boring-milling machines and machining centres manufacturer, is interested in becoming a circular-enabled manufacturer. Using the AIDEAS Industrial Equipment Repair-Reuse-Recycle Suite, PAMA will be able to increase machine performance by 15% and machine useful life by 20%.

Moreover, this suite will enable them to assess the machine's past performance, pinpoint parts with a second life in other machines, and even predict future costs and maintenance needs. This will lead to lower energy consumption and increased productivity.

Leading Developers

To download this information click HERE

Machine Passport

The Machine Passport is a digital product passport for industrial machinery that focuses on exchanging between the different suites and stages of production.

Store, share, and analyse your machine data, seamlessly.

Store, share, and analyse your machine data, seamlessly.

This platform features a comprehensive digital data repository supported by a smart management system, supporting large-scale data acquisition, management, and sharing among different devices and parties involved.

From the design phase to the crucial repair-reuse-recycle phase, this solution facilitates data exchange between end-of-life parties, including consumers, repair shops, and waste management companies.

This integrated approach allows equipment manufacturers to not only streamline processes but also guarantee a more

efficient lifecycle for industrial equipment

Main Benefits

- Faster Maintenance before failure

- Access to machine history

- Access to real-time production insights

Use Case

PAMA is using the AIDEAS Machine Passport to organise big sets of data with timestamps, including sensor readings and CNC/PLC info from when equipment is used, and maybe other data from its lifespan. Using a standardised service modeling like this will make sure all the data works together seamlessly and is accurate.

This data will help the company to make better predictions of problems in machining processes and design, build, and fix equipment in smarter ways.

With this, the Machine Passport will allow PAMA to decrease the use of materials, installation times and the overall time of the manufacturing process.

Leading Developer

To download this information click HERE

By testing AIDEAS solutions, your company can gain a competitive advantage you’ve always wanted!

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101057294